|

Experiment

#5: Last Updated October 2002 - Continued Monitoring Planned

Tin Whiskers Growing from the Terminations of Pure Tin

Plated Ceramic Chip Capacitors After Temp Cycle Followed By Ambient

Storage

|

|

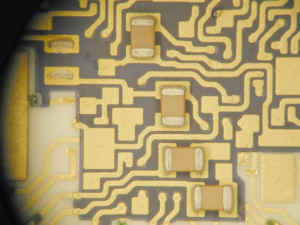

Inside of a Hybrid Microcircuit Package

with Pure Tin-Plated Ceramic Chip Capacitors

Mounted by Conductive (Silver) Epoxy

|

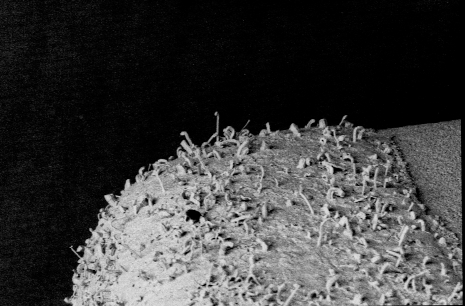

Tin Whisker Growth on Capacitor Terminations

after 200+ Temp Cycles

From -40°C to +90°C Followed by Months of Ambient Storage

(2002-Oct)

|

Purpose

Background

Interim Observations

Prior Research

Purpose:

This

experiment documents and monitors tin whisker growth on one lot of pure tin-plated multilayer ceramic capacitors

(MLCCs) mounted inside a hybrid using conductive (silver) epoxy and then

subjected to extensive thermal cycling followed by long term ambient

storage. The experiment was initiated in 2001 by a non-NASA entity

who then donated one of their test samples to NASA Goddard tin whisker

researchers for continued monitoring. Details of this study and

interim observations were formally published in June 2002 at the American

Electroplaters and Surface Finishers (AESF)

SUR/FIN conference in Chicago, IL. The paper also discusses similar

but unrelated experiments by others attempting to induce whisker growth on

tin-plated MLCCs.

- J. Brusse, "Tin Whisker Observations on

Pure Tin Plated Ceramic Chip Capacitors", AESF SUR/FIN

Conference, June 2002, pp 45-61

- Slide

presentation is also available.

The NASA Goddard

Whisker WWW Site will be used to provide updates as monitoring of these

specimens continues.

Background:

In 2001 a hybrid

microcircuit manufacturer informed NASA Goddard tin whisker researchers of

their surprising observation of profuse whisker formation on pure

tin-plated ceramic chip capacitors (MLCCs). The hybrid manufacturer

made this discovery during an evaluation intended to assess the electrical

and mechanical integrity of joints made between pure tin-plated MLCC

terminations and gold-plated substrate pads when using conductive (silver)

epoxy instead of solder reflow for mounting. Their experiments

included the following basic approach:

| Sample Preparation: Conductive

epoxy mount pure tin-plated MLCCs to gold plated termination pads

inside of hermetically sealed hybrids |

| Subject sealed hybrids to:

| Condition 1: Temperature

Cycling -40°C to +90°C for up to 500 cycles |

| Condition 2: High Temperature

Storage (+90°C) for 400 hours |

|

| Initial Results:

| Condition 1: Whiskers up to

100 um long observed after as little as 200 cycles |

| Condition 2: No whiskers found |

|

In May 2001 the

hybrid manufacturer donated one thermally cycled evaluation hybrid package

(200+ cycles per Condition 1 above) to NASA Goddard for continued

observation. The package contained 6 pure tin-plated ceramic chip

capacitors (size 0805) all reported to be from one manufacturing lot.

As received by NASA Goddard, the hybrid package had already been delidded.

The manufacturer supplied photos of the capacitor

terminations to illustrate the extent of whisker growth they observed

after temp cycle. Upon receipt at NASA Goddard the sample was reinspected

and the whisker formation was confirmed to be consistent with the extent

of growth reported by the hybrid manufacturer with all 6 capacitors

showing clear evidence of tin whisker formation. NASA Goddard has since retained

this sample in office ambient storage for

ongoing observation and analysis.

NOTE: The hybrid

manufacturer reports they originally intended to use

palladium/silver terminated capacitors in an application where the

capacitors were to be mounted to a substrate using conductive epoxy.

Erroneously, the supplier of the capacitors provided pure tin plated

capacitors (standard commercial offering) to fill the user's order.

CAVEAT EMPTOR. The hybrid manufacturer noticed a visible difference

in appearance of the termination finish at incoming inspection. The

subsequent evaluations were initiated to determine if the mistaken

shipment of capacitors could be used for production anyway.

Interim (Summary) Findings

(reverse chronological order):

|

|

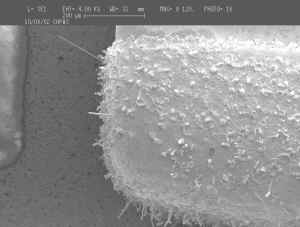

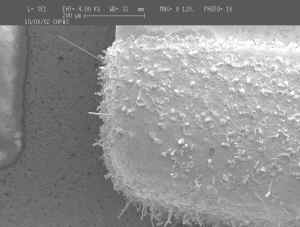

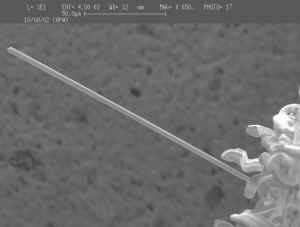

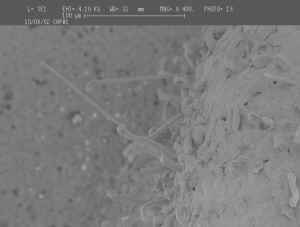

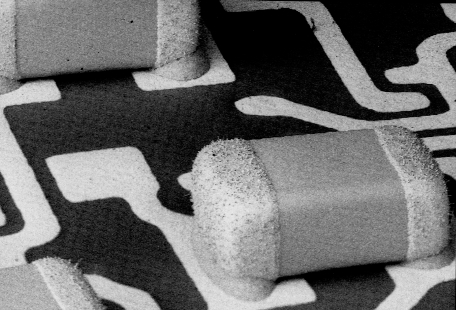

October 2002 - Photos Below are

from Same Capacitors T-cycled in early 2001 then stored in Ambient Office

Conditions

Courtesy NASA Goddard Space Flight Center Parts

Analysis Lab |

|

|

|

|

|

|

|

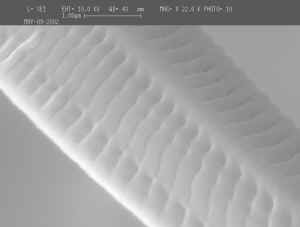

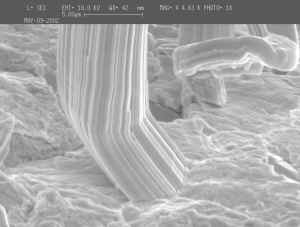

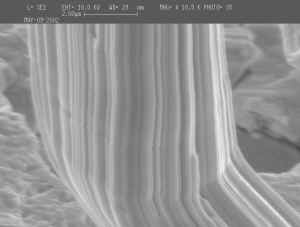

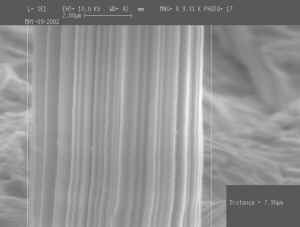

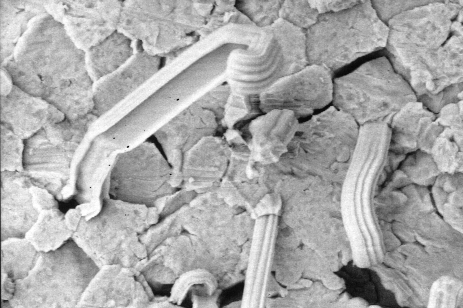

May 2002- High Power SEM Images

to Show How SOME of the Whiskers have Circumferential Rings

Courtesy of NASA Goddard Space Flight Center |

|

Longest Whisker Found ~ 240 microns

|

Whisker "#1" - Overall View |

Whisker

"#1" - Base of Whisker |

Whisker "#1" - Middle of Whisker (Notice

"Rings") |

Whisker "#1" - Tip of Whisker (Notice

"Rings") |

Whisker "#1" - Close Up of

"Rings" |

Whisker "#2" - Overall View |

Whisker "#2" - Base of Whisker |

Whisker "#2" - Kink Near Base (Notice

"Rings") |

Whisker "#2" - Tip of Whisker (Notice

"Rings") |

Whisker "#2" - Close Up of Tip (Notice

"Rings") |

Whisker "#2" - Middle of Whisker (Notice

"Rings") |

|

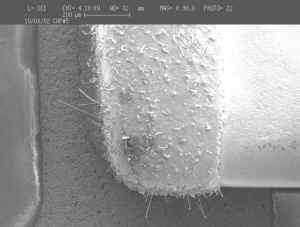

December

2001: ~ 6 to 8 Months of Ambient Storage Have Elapsed Since

the Thermal Cycle Exposure

| The sample hybrid (with chip caps still mounted) has

been stored at ambient condition ever since being received at GSFC. |

| SEM inspection in December 2001 shows that some of

the tin whiskers on the chip caps have grown substantially since the

previous inspection. A few whiskers are now greater than 200

microns long (some approaching 250 microns). Previous examination in

August 2001 showed maximum whisker length was approximately 100

microns. |

| Capacitors will be retained for additional ambient

storage and inspection |

|

|

|

|

|

|

|

|

|

|

|

August 2001 -

NASA Goddard Inspection to Confirm Observations Reported by Hybrid

Manufacturer

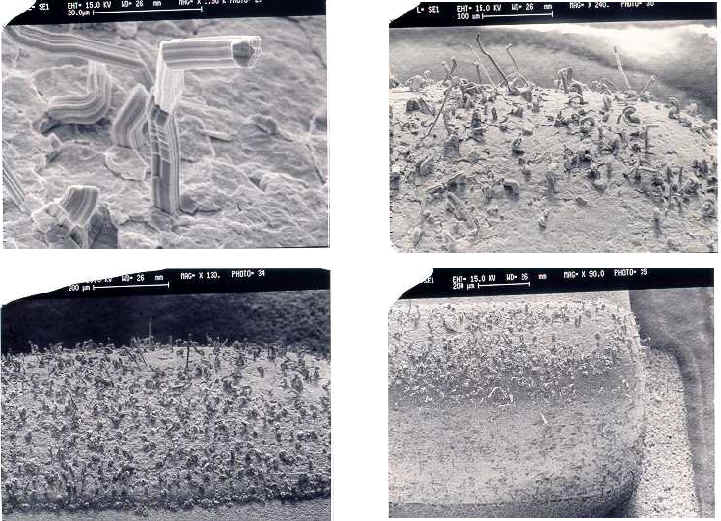

Q1. What is the max length of whisker and

typical length of whisker? Quantify typical length of whiskers.

A1. The max length of whisker was estimated to be 100 um

and the typical length is estimated to be around 25um to 50 um.

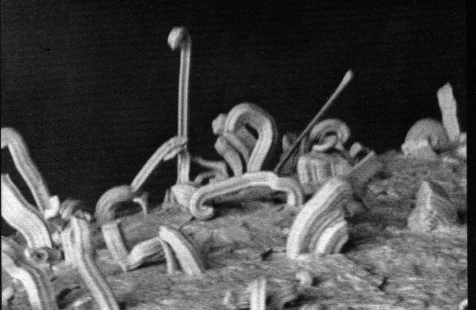

This cap is populated with mainly two types of whiskers: toothpaste like

(thick curly type) and needle like. The density of the whiskers

(including both types) is estimated to be 800 whiskers/mm2 (conservative

estimate) which can be compared to GSFC experiment using pure tin plated

brass substrates with ~50 whiskers/mm2 (max density sample). Among

entire whisker population, 5% is needle like whiskers that would grow

potentially dangerously long.

Photos Courtesy of NASA Goddard Space

Flight Center

Q2. EDAX on the cap termination to confirm if

there's any lead (Pb) content?

A2. EDAX results showed Sn element exclusively. No Pb

was observed (Accuracy: Elapsed time was 500 sec.).

Q3. Examine whisker growth at the

conductive epoxy interface, and WITHIN the conductive epoxy?

A3. The whiskers are present only on plated termination on

both sides of the caps. No whiskers were observable at the

conductive epoxy interface nor within the conductive epoxy.

Q4. Analyze the grain structure of the

plating (quantify grain size) if possible.

A4. This could not be done with SEM. Future Work will attempt

to analyze the grain structure using Oriented Imaging Microscope (OIM) for

grain structure analysis |

|

February 2001-Photos Below Were Taken Shortly

After 200+ Temp Cycles from -40°C to +90°C

Courtesy of I. Hernefjord |

|

|

|

|

|

|

|

Previously

Published Research on MLCCs and Tin Whiskers:

Prior to 2002

published research has suggested that multilayer ceramic capacitors (MLCCs)

are "immune" to the risks of whisker formation. Research by Murata**

(M. Endo 1997) showed 18 years of whisker-free performance of pure tin

plated MLCCs when stored continuously at 50°C. In

summary, the rationale given for this protection included:

| Use of Nickel

barrier metallization under the tin electroplate |

| Use of

"Matte" tin plating chemistries and processes |

| Relatively

"large" (>5 um), well-polygonized tin grains |

| Post

electroplating annealing processes |

** M. Endo, S. Higuchi, Y. Tokuda, and Y. Sakabe, "Elimination of Whisker Growth on Tin Plated Electrodes", Proceedings of the 23rd International

Symposium for Testing and Failure Analysis, pp. 305 - 311, October 27-31,

1997

|