|

|

|

|

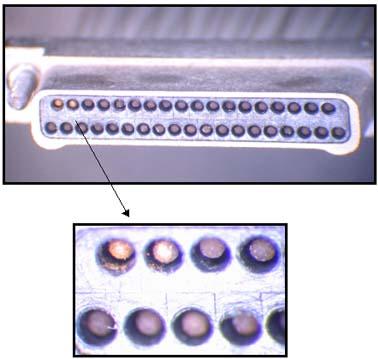

Connector Corrosion |

|

3. Connector Corrosion

The photo above is a wiring harness consisting of a recessed 37 pin Durolobe pin type connector in an electroless nickel plated shell with 30 AWG seven strand silver plated high strength copper wire, with white fluoropolymer insulation. The harness had been stored in a plastic bag (polyethylene) and the connector shell, gold plated Durolobe pins, and exposed wires were observed to have been degraded. The harness had passed incoming inspection and was later found to have degraded upon storage. Due to the potential continuing degradation of the harness it was recommended that the harness be scrapped.

The top left two pins on the above connector were scraped showing base Beryllium Copper material. The remaining pins show corrosion due to active fluorine resulting from being stored in a plastic bag (polyethylene).

Reference :

NASA-STD-8739.4

6.9 In-Process Storage and Handling

1. Each supplier performing soldering operations shall develop and implement requirements and procedures that control conditions to prevent damage to, and degradation of, parts and deliverable items. In particular, means shall be provided to prevent damage or contamination to printed wiring terminating areas, terminals, connectors, wire ends, or part leads during handling and storage. Containers shall be compatible with materials stored therein.

|

|

|