|

|

|

|

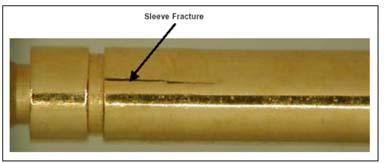

Socket Sleeve Fracture |

|

7. Socket Sleeve Fracture

The above photo shows a fractured sleeve on a 22D socket contact. The purpose of the sleeve is to center and guide the pin contact into the engagement tines of the socket contact during the mating process. The sleeve fractures resulted in loosening of some of the contact sleeves. The loose sleeves are a concern if the sleeves inadvertently fall off during handling prior to installation into connectors. In addition contacts with fractured sleeves may cause a problem if the sleeves are removed and the contact engagement tines become damaged.

Reference :

NASA-STD-8739.4

Crimp Connections

12.1 General

1. Crimped connections shall be inspected 100 percent in order to verify compliance with this standard.

12.2 Examination of Crimp Contact For manual crimping operations prior to wire insertion, the assembler shall examine the crimp contacts. Contacts that show the following conditions shall not be used. 1. Cracks in the plating or base metal. 2. Tarnishing or discoloration of the plating. 3. Plating removal or flaking. 4. Out-of-roundness of the wire well entrance. 5. Exposed base metal

A visual inspection of all uninstalled contacts should be done under a 4x-10x magnification to check for cracks.

For flight hardware, only the crimped or dimpled contact is acceptable. Contacts that have missing sleeves should be replaced.

|

|

|