|

|

|

|

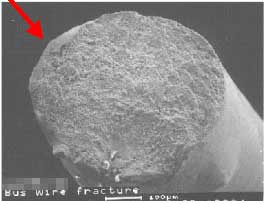

Buswire Fracture from Nick in Lead |

|

1. Components

Buswire fracture due to nick in lead

This image shows a fractured bus wire caused a nick in the lead. Historically, this criterion is one of the areas NASA's workmanship standards have departed from other standards - most of which allow nicks, cuts, or scrapes as long as they don't exceed 10% of the diameter of the conductor (a quick measurement will show this nick to be somewhere between 5 and 10 percent of the lead diameter). In NASA's vibration and thermal cyclic environment, any lead damage other than smooth indentations, usually caused by round nose pliers during lead forming, can easily propagate through the entire lead.

Reference :

NASA-STD-8739.3, paragraph 8.1-6d:

Whether formed manually or by machine, part leads shall not be mounted if they show evidence of nicks or deformations. Smooth impression marks (base metal not exposed) resulting from tool holding forces shall not be cause for rejection.

Secondary references:

NASA-STD-8739.2, paragraph 8.7-4b:

There shall be no evidence of cracks, nicks, or chip-outs in the part or substrate area.

NASA-STD-8739.4, paragraph 10.1-3:

After removal of the conductor insulation, the conductor shall not be nicked, cut, or scraped to the point that base metal is exposed. Conductors that were reduced in cross-sectional area shall not be used.

|

|

|