Anecdote

#5: Field Failures Due to Tin Whiskers on "Bright"

Tin-Plated Circuit Breaker Contacts

Click on the Thumbnails Below

to see a Larger Version of the Picture |

|

Source:

Anonymous (Terrestrial Application)

Date: Field Failures

First Observed Circa 2003

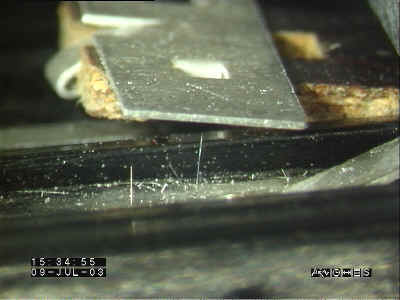

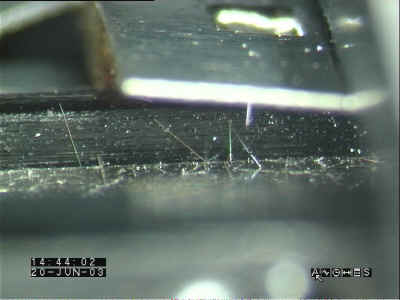

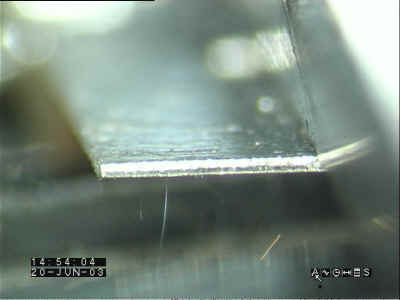

The images below

depict tin whiskers growing on the "bright" tin-plated

copper contacts inside of a circuit breaker.

Two to three years after deployment of these components into (terrestrial) service,

the user began to experience field failures in multiple locations

across Europe. Failure analysis identified the root cause of failure

to be tin whisker induced short circuits across contact pairs that

are normally open circuit. During failure

analysis the user observed that the density and length of whiskers were

greatest in the

areas of the contacts exposed to highest electric field in operation (i.e., between the separated contact pairs

having 50V potential

difference). Read

More about this experience below.

|

Tin Whiskers Growing on "Bright"

Tin-Plated Copper Contacts Inside a Circuit Breaker |

|

|

|

|

|

|

The

procurement requirements for this

circuit breaker specified the contacts to have "reflowed" tin

finish over copper. Due to a purchasing/supplier error that spanned a

period of ~2 years, the user received a number of devices (such as those

depicted above) whose contacts were "bright" tin-plated, non-reflowed

over copper. Within 2 to 3 years of fielding the "bright"

tin-plated components, the user began to experience tin whisker induced

failures. Field conditions for this component are typically

air-conditioned spaces, but the component operates at 35°C to 40°C

average due to its location within the equipment rack.

The user

also reported the following interesting observations:

-

During normal

application, there is a 50V bias across the open circuit contacts. In

the "biased area" where the electric field is highest, the

tin whisker lengths reached in excess of 2 - 4 mm which is

sufficient to bridge the gap between the separated contacts resulting

is device failure. One picture

shows a tin whisker that is bending where it is squeezed between the separated contacts.

-

Tin whiskers were also

observed in areas away from the biased region, but the density and

maximum lengths were significantly less (~1 mm maximum) than found in

the biased regions.

-

Tin whiskers were also

found on spare parts taken from inventory (i.e., warehouse storage,

unbiased) having the same lot date codes as the field failures.

Whisker lengths for the parts taken from inventory were much shorter and whiskers were more randomly distributed

(i.e., not

more prevalent in the gap areas).

-

Based on observations

1, 2, and 3 the user postulates that electrical bias (open circuit)

may have an accelerating effect on tin whisker growth especially for

"bright" tin finishes.

-

The user reports good field performance history

(i.e., no failures) for breakers whose contacts were "reflowed tin finish"

as originally specified.

Source: Anonymous by Request |

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()