|

This Photo Gallery contains examples of

EEE Parts and related hardware that have grown metal whiskers. This

photo gallery is by no means a complete archive of the types of parts that

have been known to whisker, but instead contains only those part types for

which NASA GSFC has been able to obtain permission to share photographic evidence.

The growth of whiskers

is NOT unique to a specific part type but rather is related to the materials

and processes used to plate the components as well as the subsequent

environment/handling conditions to which the parts are exposed. As such, users are urged

to exercise caution when selecting components that are plated with

materials and processes that are prone to whisker formation.

Photo of

the Month Archive

|

EEE Parts

|

Mechanical Hardware and Structures

|

- Capacitors

Circuit Breakers

Connectors

Crystals

|

- Discrete Semiconductors

Electromagnetic Relays

Hybrids and Microcircuits

Resistors

Transformers

Wave Guides

|

- Bus Bars and Rails

Cable Trays

Card Guides

Floor Tiles, Raised Computer Room

Hardware

Pipe/Conduit

Terminal Lugs

| Terminal Lugs, Ring Type,

Tin-Plated |

| Terminal Lugs, Spade Type,

Tin-Plated |

| Terminal Lugs, Ring Type,

Tin-Plated, Mfr "A" |

| Terminal Lugs, Ring Type,

Tin-Plated, Mfr "B"

|

Test Points

|

Capacitors

Capacitor, Multilayer Ceramic Chip

These commercial

(size 0805) ceramic chip capacitors have pure tin plated

terminations over a nickel barrier layer. The user mounted them using conductive epoxy (i.e, not

reflow soldered) and after thermal cycle testing discovered the tin

whisker farm. After thermal cycling max. whisker lengths of 100

microns were observed. HOWEVER, after additional room ambient

storage (6 - 8 months) the whiskers continued to grow with some in excess

of 200 microns (max. length ~240 microns). It has NOT been experimentally shown whether soldering these parts to the board

would have eliminated the whisker concern through either reflow of the

terminations or mixing of "most" of the termination surface with

the mounting solder (typically tin/lead based). See NASA

GSFC Experiment #5 for more info.

|

Epoxy Mounted Cap:

whiskers on terminations

|

Top Side of Termination

Tin whiskers on terminations

|

Close Up:

Tin whiskers on terminations

|

Close Up:

Tin whiskers on terminations

|

|

Tin Whiskers continued to grow during room ambient storage after

completion of t-cycle

|

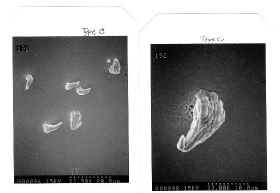

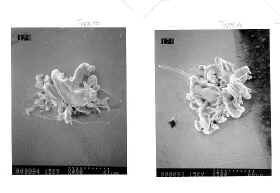

Various odd-shaped Tin whisker extrusions

|

>150um long Tin whisker

|

More Tin whiskers

|

|

Close Up:

Tin whiskers on termination

|

190um long Tin whisker

|

|

|

Photos

Courtesy of I. Hernefjord & NASA Goddard

Capacitor, Variable Air Spaced

In 1946 Howard Cobb of the Aircraft Radio Corporation

(ARC) published an article "Cadmium Whiskers" that many consider

to be the first public reference describing how metal whisker growth

affected the proper functioning of electronic systems. In his

article he describes how cadmium whisker formation on the cadmium-coated

plates of variable air-spaced capacitors were producing plate to plate

short circuits in radio equipment used during World War II. The news

that cadmium coatings could produce damaging whiskers reached others such

as Bell Laboratories (less than 20 miles from ARC) who switched from

cadmium to tin and zinc coatings only later to discover that these metals

also sometimes produce damaging metal whiskers.

The specimen shown below is a 1960s era variable

air-spaced capacitor (similar to the one described by Cobb) that uses a

tin-plated frame. The extensive tin whisker formation on this capacitor

extend in excess of 8-millimeters in some cases. NASA Goddard greatly

appreciates Frank Nikolajsen, a vintage radio collector in Denmark, for

contacting us and then donating this treasure piece for analysis and

historical preservation.

See

a video of this air capacitor demonstrating their extreme lengths and

flexibility in normal air flow

Images courtesy of NASA-GSFC

Circuit

Breakers

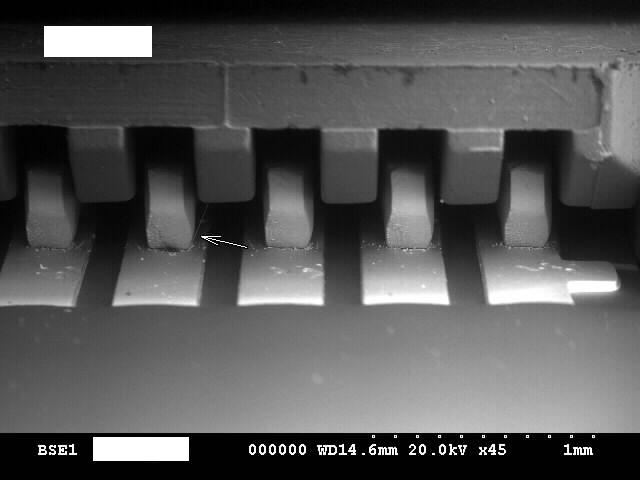

Circuit Breaker Contacts

The

images below depict tin whiskers growing on the "bright"

tin-plated copper contacts inside of a circuit breaker.

Read

More About the Field Failures Experienced as a Result of the Tin Whiskers

on These Circuit Breakers

Source: Anonymous

Connectors

Wire Wrap Terminals

Tin-plated wire wrap terminals below grew a very high

density (#/area) of tin whiskers having sufficient length to bridge

adjacent terminals.

Read more about this experience in the following GE

Power Management Service Bulletin

Images courtesy of GE Industrial

ZIFF Socket

ZIFF Socket below has tin whiskers growing from tin-plated

surfaces immediately adjacent to areas where the pin presses against the

contact.

Metal whisker growth has frequently been observed in applications where

surfaces are subjected to externally applied pressure.

Source - anonymous (circa 2006)

ZIFF Socket with Tin Plated Surfaces |

Tin Whisker on ZIFF Socket |

Tin Whisker on ZIFF Socket |

Tin Whisker on ZIFF Socket |

Source: Anonymous

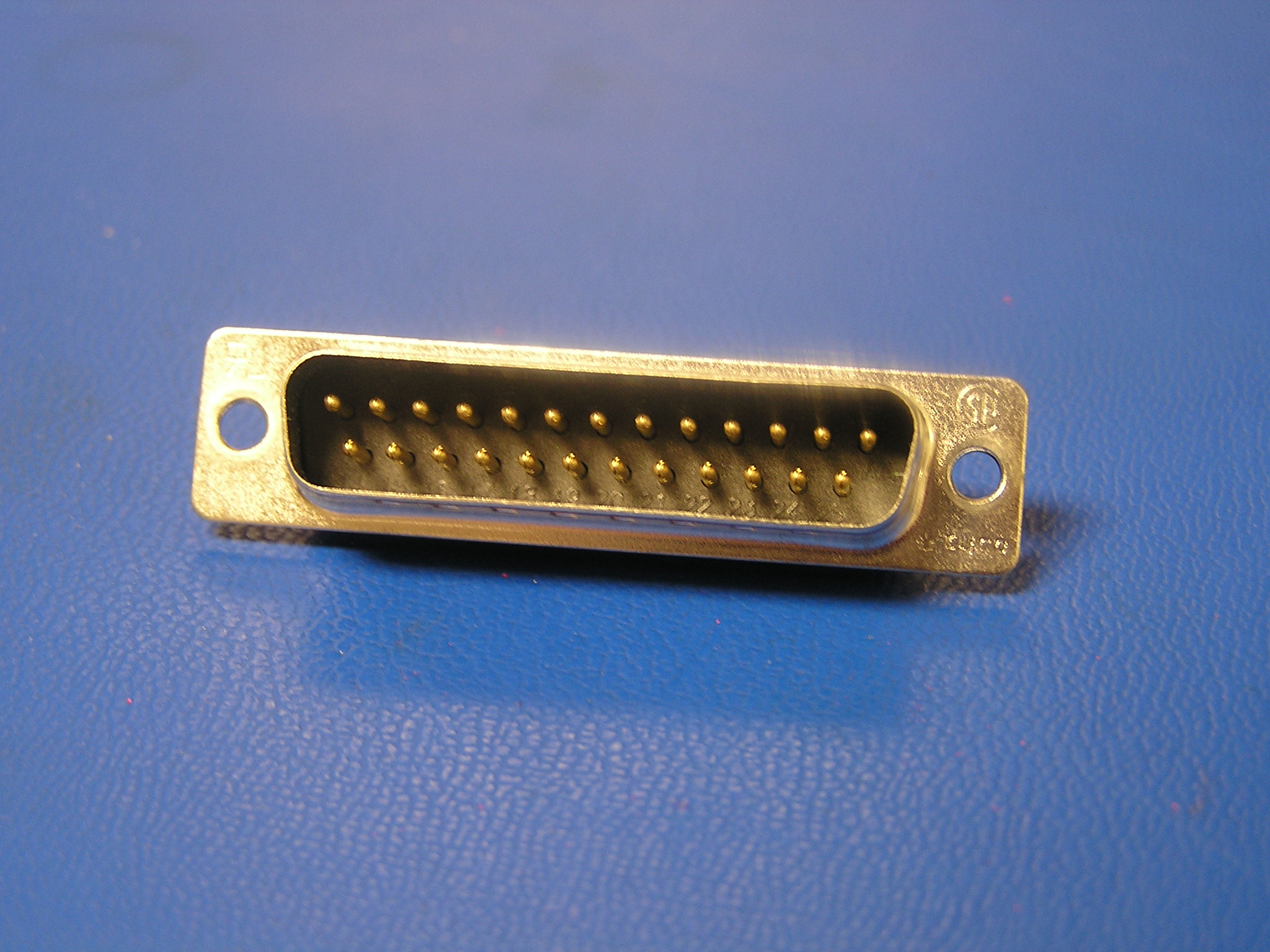

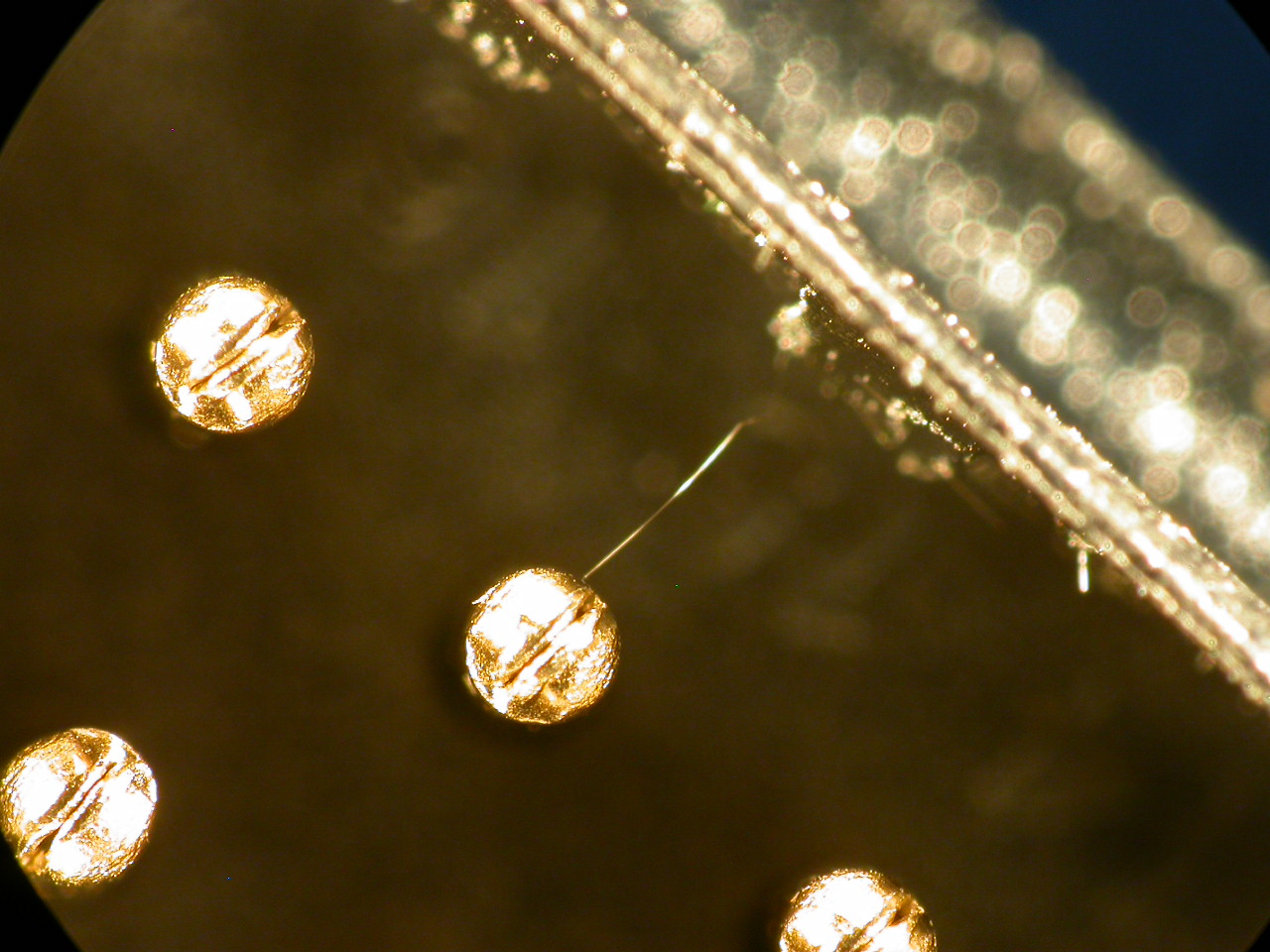

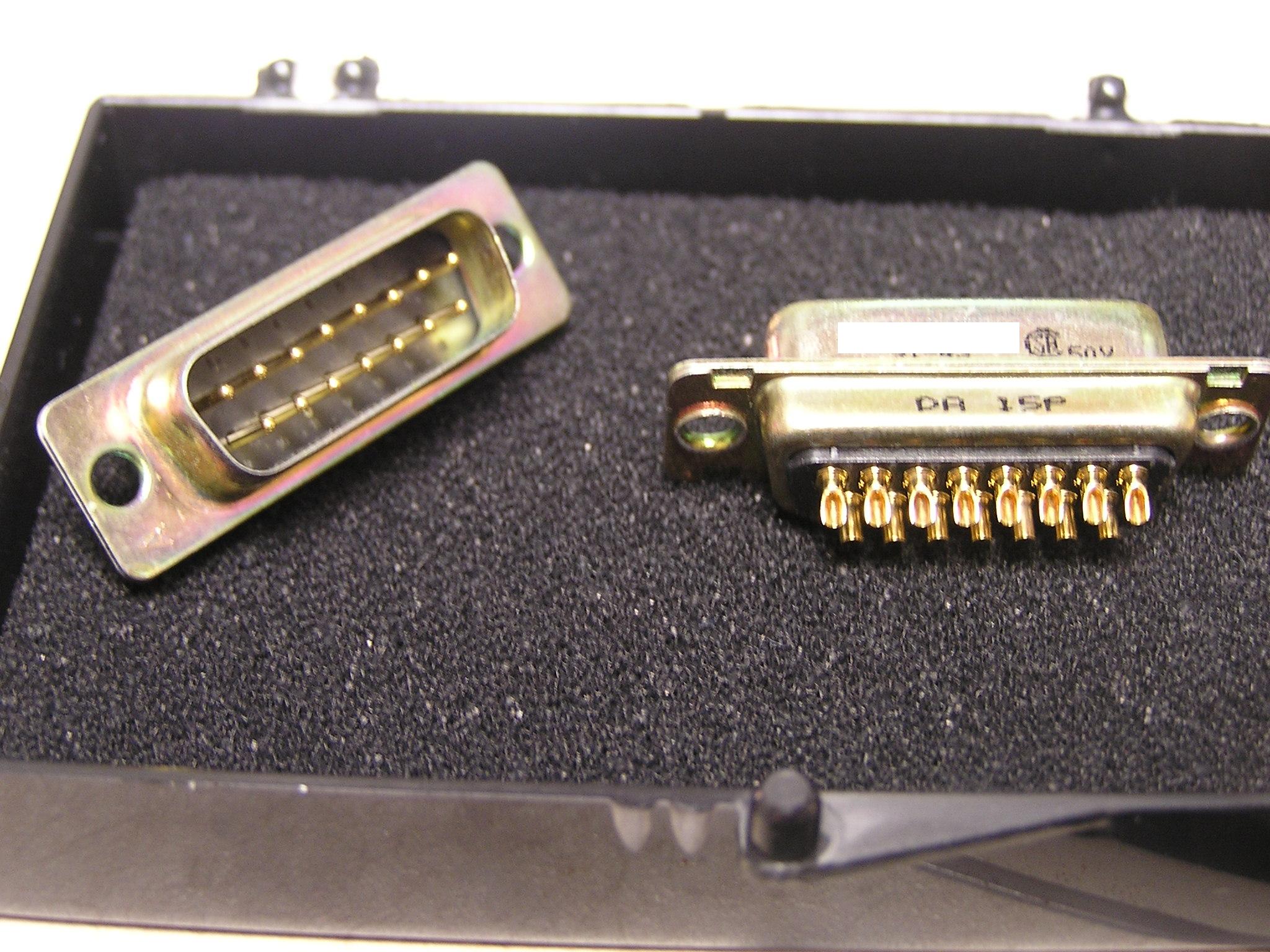

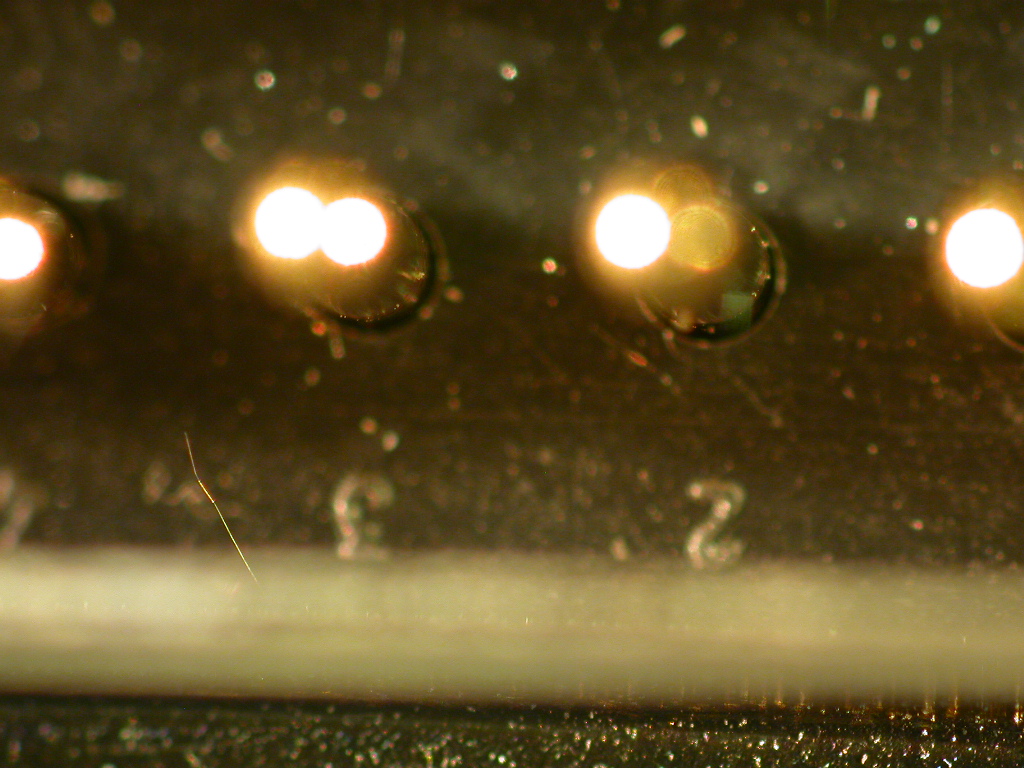

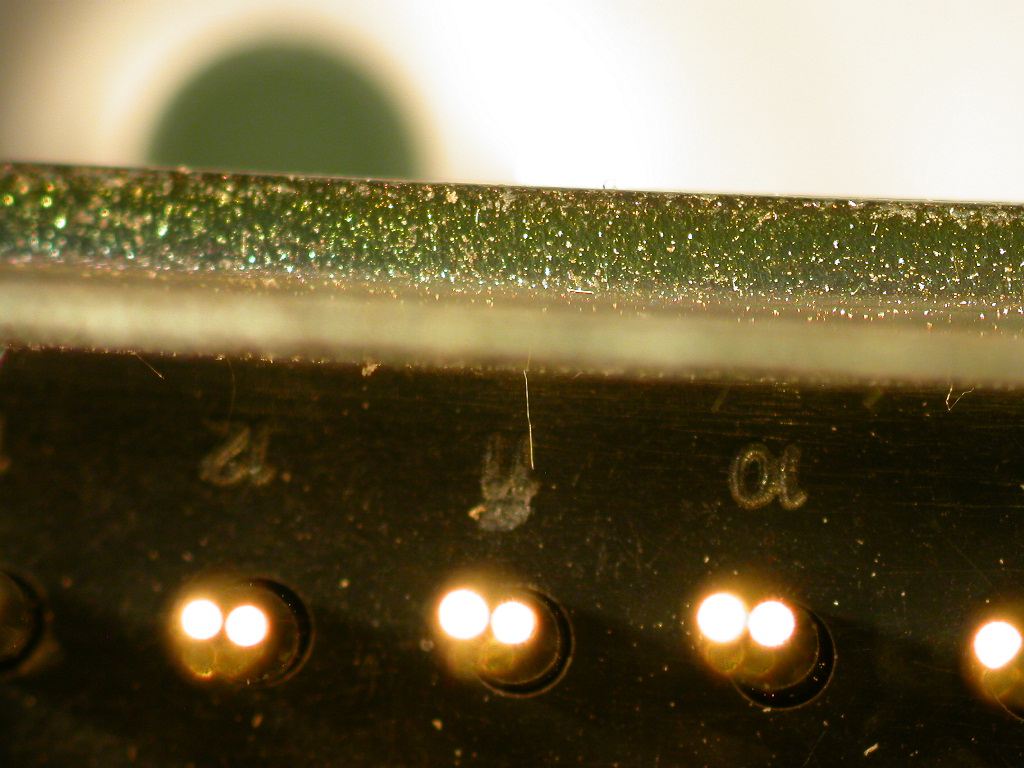

Connector, D-Sub, Tin-Plated Shell

Connector shells are often plated with tin, zinc or

cadmium finishes for corrosion protection.

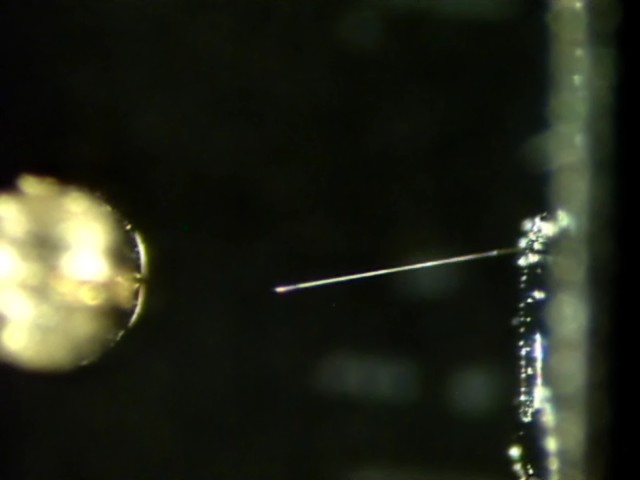

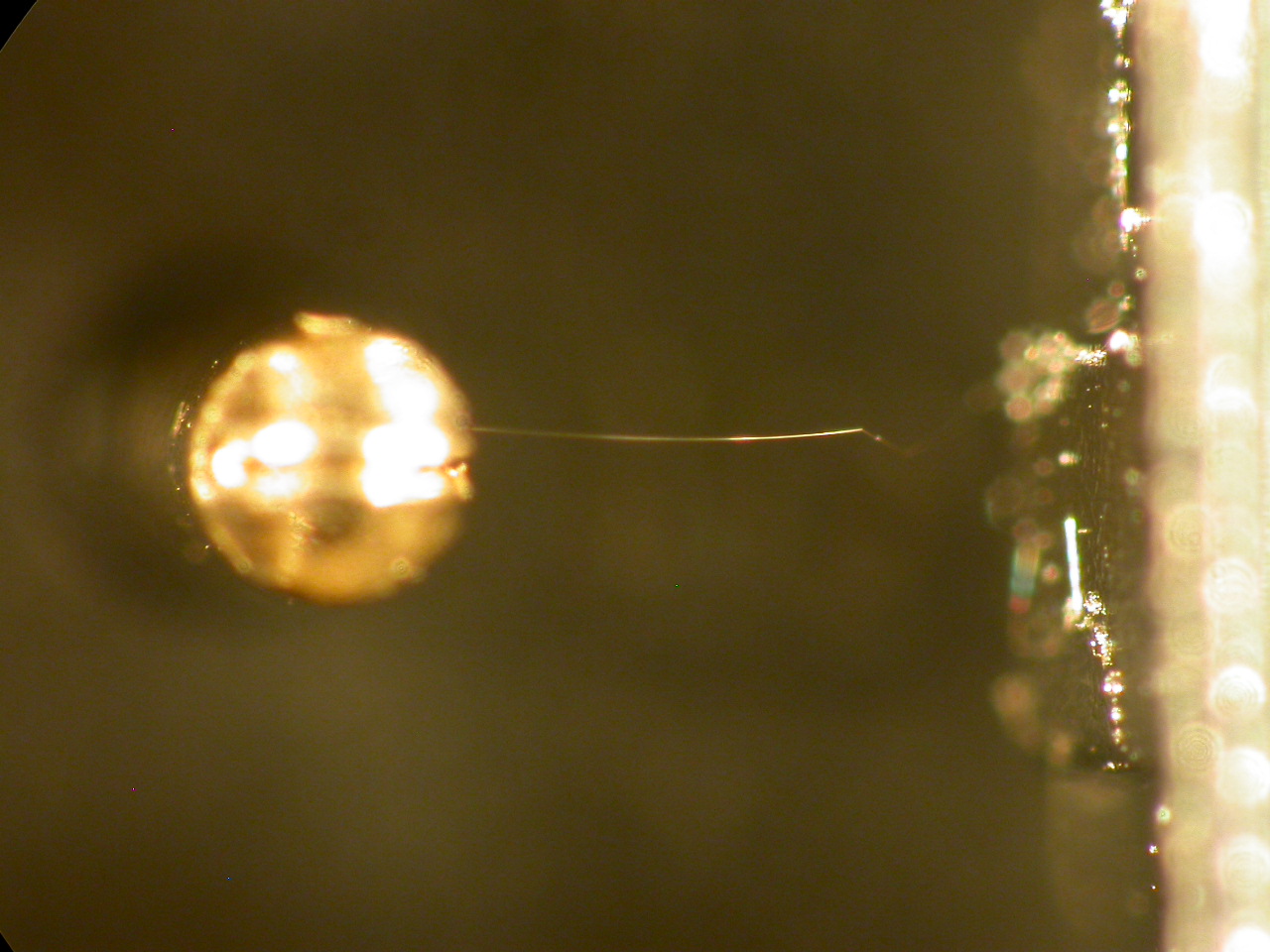

The examples below show tin whiskers and zinc whiskers growing from

D-subminiature connector shells including an example of a whisker bridging

from the connector shell to a gold-plated connector pin

|

Tin-plated D-Sub Connector Shell

|

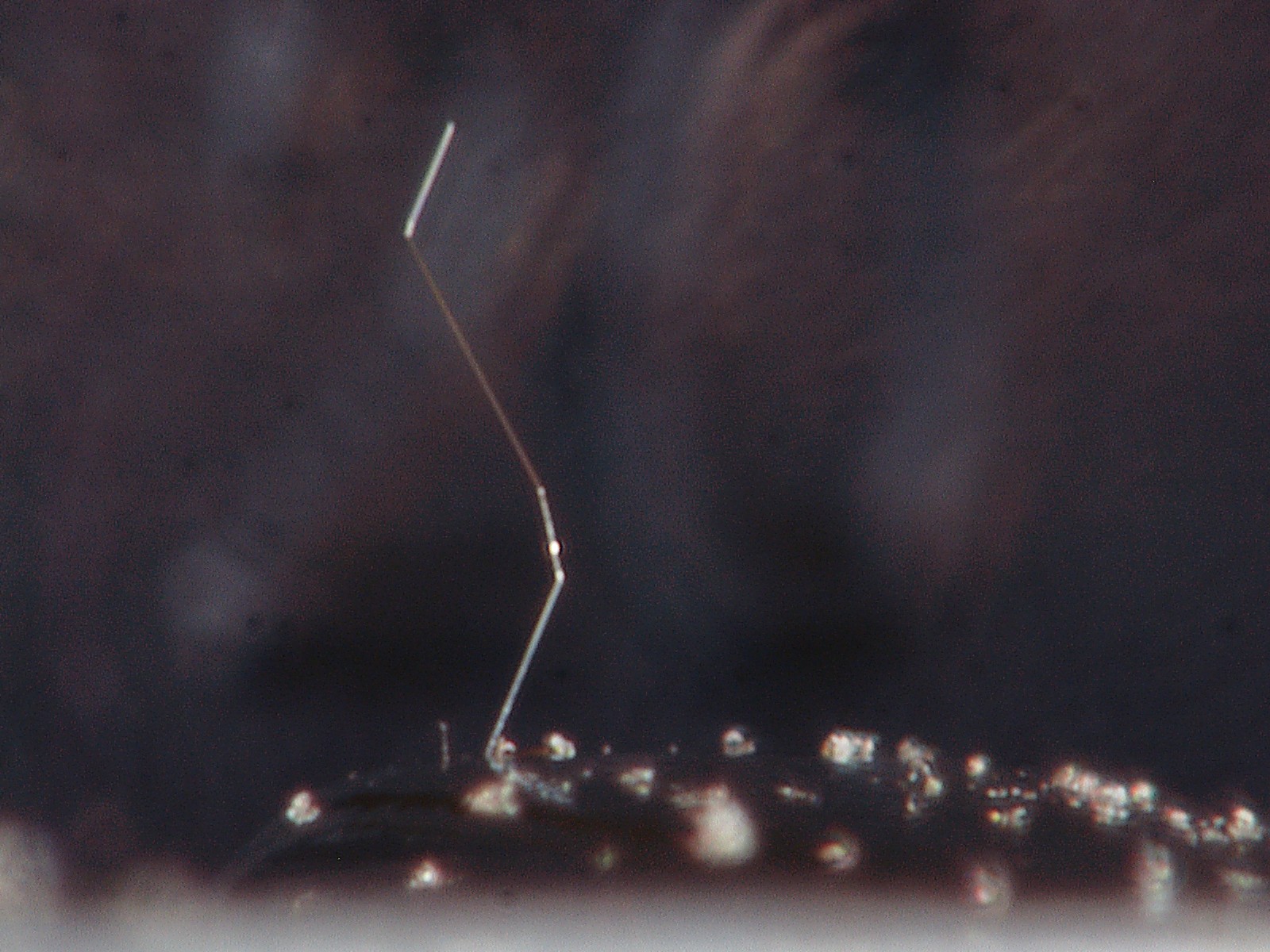

Tin whisker growing from connector shell

|

Tin whisker shorting connector shell to pin

|

|

Tin Whiskers on DSub Connector Shell

Photo taken in 2006

|

Tin Whisker on DSub Connector Shell

Shorting to Connector Pin

Photo of previous whisker 2 years later

|

Tin

whisker shorting connector shell to pin

|

Images Courtesy of NASA-GSFC

Connector, D-Sub, Zinc-Plated

Shell

|

Zinc-plated D-Sub Connector Shell with Yellow Chromate Conversion

Coat

|

Zinc Whiskers on D-Sub Connector Shell

|

Zinc

Whiskers on D-Sub Connector Shell

|

|

Zinc

Whiskers on D-Sub Connector Shell

|

Zinc

Whiskers on D-Sub Connector Shell

|

Zinc Whisker

detached from D-Sub Connector Shell

|

Images Courtesy of NASA-GSFC

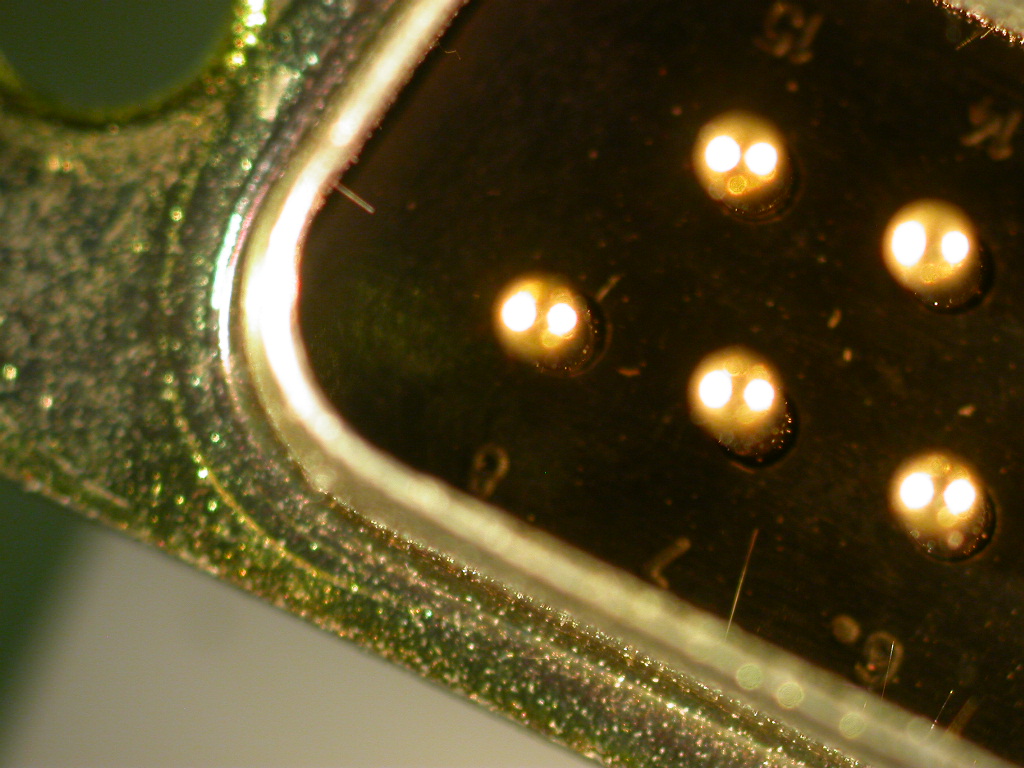

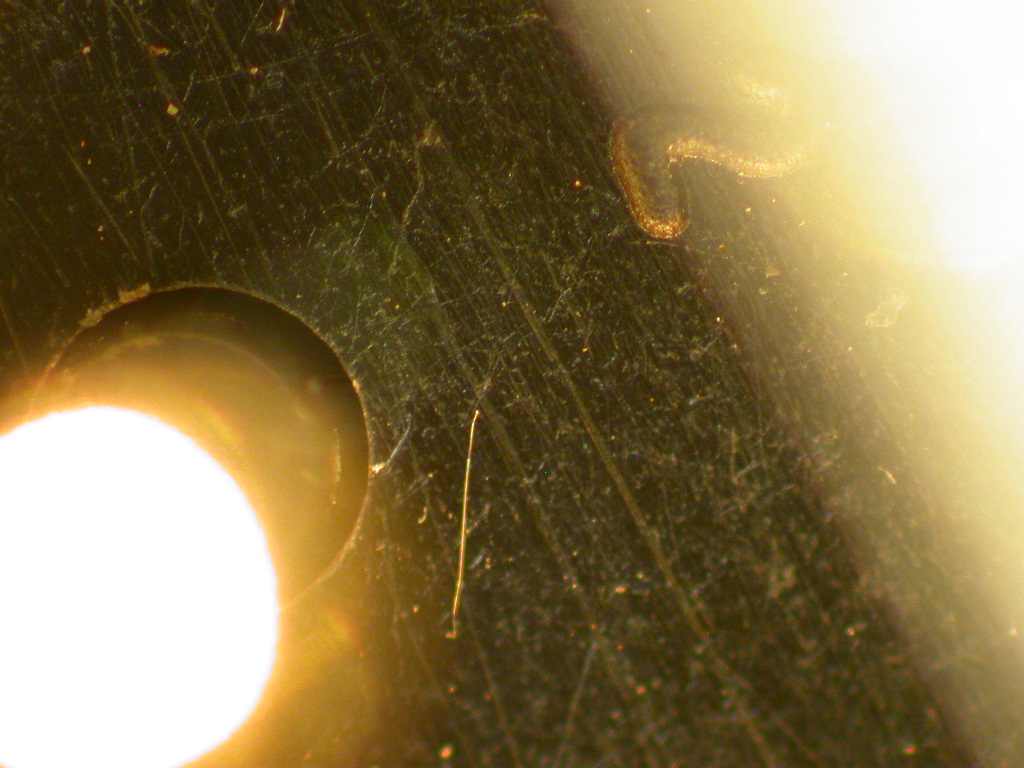

Connector, Circular,

Cadmium-Plated Shell

The following circular connector shell is

CADMIUM-plated. Connectors like this were used as feed-thrus on a

thermal vacuum test chamber. The cadmium whisker formation on this

shell resulted in shell to pin electrical short circuits that interrupted

testing of space flight hardware.

Source: Anonymous

Connector, Universal Serial Bus (USB),

Video Monitor

Universal Serial Bus (USB) connectors frequently have tin-plated

surfaces. The following photos show tin whiskers forming on USB

connectors used on video monitor circuit card assemblies.

Read

More About these USB connectors from CALCE's www site here:

Images Courtesy of CALCE-University of Maryland

Connector, Universal Serial Bus (USB),

Mother Board

Universal Serial Bus (USB) connectors frequently have tin-plated

surfaces. The following photos show tin whiskers forming on two

different types of USB connectors used on PC motherboard circuit

card assemblies.

Read

More About these USB connectors from CALCE's www site here:

Images Courtesy of CALCE-University of Maryland

Connector, Octal Type

The connector below is an octal type connector with

circular cross-section pins on the plug-in side (left side of first image

below) and rectangular cross-section pins on the right angle mount

solderable contacts (right side of first image). The pins are pure

tin-plated. Tin whiskers were found on the rectangular cross section

pins while performing an inspection of a module reported to have failed in

a commercial electric power utility application due to tin whisker shorts

originating from a microcircuit also used in this assembly.

Octal type connector with pure tin plated pins |

Wide view of pin shows some tin whiskers. |

Tin whisker on pin |

c

Tin whisker on

pin |

Tin whisker on

pin |

|

Images Courtesy of NASA-GSFC

Crystal

Crystal, Tin-Plated Case

The leads on this crystal are made of Kovar (Fe-Ni-Co

alloy) with a Nickel barrier layer having a final pure tin finish.

Prior to installation the user dipped the leads into tin-lead solder to

improve solderability. However, a small portion of the leads (close

to the package) remained pure tin finish. This pure tin region

produced tin whiskers that shorted the lead to case causing field failures

Read More about this

Crystal and the Benefits & Limitations of Hot Solder Dip to Mitigate

Tin Whisker Growth

Source: Anonymous

Discrete

Semiconductors

Diodes, Axial

Lead, Tin-Plated

Axial-leaded diodes having tin-plated terminals have

exhibited tin whisker formation.

In 2005 the Dominion Millstone Nuclear Power Station experienced a reactor

shutdown that was traced to an inadvertent alarm signal produced by a tin

whisker short circuit from diodes like these.

Read

the article here:

Image Courtesy of Dominion-Millstone Power Station

Images Courtesy of T. Riccio/STPNOC

Transistor, Metal Case,

Tin-Plated

The package of these transistors used extensively in

vintage radios is tin-plated. Tin whiskers growing on the internal

surfaces of the package have produced short circuit failures of these

transistors.

Read

More about these Transistors and how a community of vintage radio

collectors have combated the mysterious source of electrical short circuit

failures.

Images Courtesy of NASA-GSFC and Paul Stenning

Electromagnetic

Relays

Relay, Electromagnetic,

Tin-Plated Steel Armature

The hermetic relay shown below (age ~14 years) has an iron

armature that has been plated with PURE TIN. The armature is

INTERNAL to the packaged relay and cannot be seen by the user unless the

device is destructively opened for analysis. As noted by the images,

numerous tin whiskers are clearly visible (even via naked eye inspection)

growing from the armature. Some whiskers are approaching 3 mm in

length which is more than sufficient length to create a short internal to

this device.

Read

More About the Failures Attributed to Metal Vapor Arcing initiated by tin

whiskers inside this relay.

See

a Video of Whiskers Inside this Relay Demonstrating Extreme Flexibility

When Subjected to Air Currents

Specimen and damaged

relay photos supplied by G. Davy/Northrop Grumman

Whisker Photos courtesy of NASA GSFC

Relay, Electromagnetic,

Tin-Plated Case, Terminals & Header

The Relays shown below

are plated with pure tin. This plating exists over the entire case,

header and the hook terminals that will normally have stranded wire soldered to

the end of the hooks. Whisker shorts can occur due to whiskers

growing from either the case, header or the terminals. Even when

terminals have wire soldered to the hooks, whiskers have been observed

growing from the base of the terminals near the glass to metal seals.

Images

Courtesy of NASA-GSFC

Tin whiskers on terminals |

Tin whiskers on terminals

|

Tin whiskers on terminals |

Tin whiskers near glass seal

|

Tin whiskers near glass seal |

Close up of Tin whisker growths |

close up of Tin whisker growths

|

Tin whiskers near glass seal

|

Images

Courtesy of Space Systems Loral

Hybrids and

Microcircuits

Hybrid Microcircuit

The photo below is of the package lid of a hybrid microcircuit.

The lid was plated with pure tin. This whisker was found growing on the on

the surface of the lid that was facing INSIDE the of the device.

Other whiskers were also found on the lids with some as long as 2

mm.

In previous (unrelated) reports, whiskers similar to the one shown below

on hybrid package lids have been reported to cause field failures in

Phoenix Missiles1 and F-15 radar systems2

1) L. Corbid, "Constraints on

the Use of Tin Plate in Miniature Electronic Circuits", Proceedings

3rd International SAMPE Electronics Conference, pp.

773-779, June 20-22, 1989.

2) B. Nordwall, "Air Force

Links Radar Problems to Growth of Tin Whiskers", Aviation Week and

Space Technology, June, 20, 1986, pp. 65-70

Images

Courtesy of NASA-GSFC

Tin Whiskers growing on a MATTE tin-plated copper leadframe commonly used in the manufacture of 28 pin small outline integrated circuit (SOIC) leadframe after 3 years of ambient storage.

Photos

Courtesy of Peter Bush (State University New York at Buffalo)

Resistors

Potentiometers

In 2005 Westinghouse Nuclear published a service

bulletin describing how metal whisker formation on certain

potentiometer cans could produce power supply interruptions.

Images Courtesy of T. Riccio/STPNOC

Potentiometer,

Internal Structures

The following potentiometers were used as calibration pots

in oscilloscopes from the 1970s. Mis-operation of the oscilloscope

were diagnosed to be the result of the metal whiskers growing from the

internal components of the potentiometer shorting its case to the wiper..

Images courtesy of Alan Douglas/UK

Vintage Radio Forum

Transformers

Transformer Cans

The supplier of these transformer cans originally supplied

them with tin-lead (Sn-Pb) finishes. In response to international

legislation (e.g., RoHS) they switched to pure tin coatings without

changing part numbers nor issuing a product change notice to their

customers. Fortunately, for the user who provided NASA Goddard with

these samples, the external appearance of the cans was different enough to

encourage him to provide them to us for a closer look. Thanks to Steve

Battel for sharing these samples with us.

See

a Video of these transformer cans

Images

Courtesy of NASA-GSFC

After receiving these pictures of concern the supplier

responded:

"We appreciate your loyalty for so many years and your

email concerning the whisker growth. The push to be RoHS compliance has caused us to switch our plating process

and introduce new materials that are environmental friendly but they in

turn created other problems. I sent your concerns to our product manager and I hope we can do something

about it."

Wave

Guides

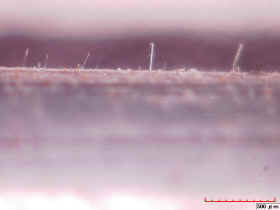

Wave Guide, Tin-Plated Flange (Documented in 2004)

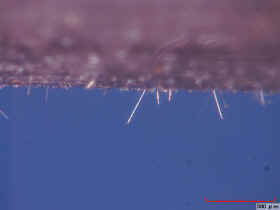

The images below depict tin whiskers found growing from

the tin-plated flange of a Ka band waveguide. The high density of

whiskers, some approaching 5-mm long, were found within several weeks of

receipt of product by the waveguide user. In the end application whiskers

of this size and density produced signal reflections and losses that

affected the electrical performance of the waveguide.

Read

More about the Tin Whiskers Found on this Wave Guide

Images

Courtesy of Ingemar Hernefjord

Mechanical Hardware

and Structures

Bus

Rails and Bus Bars

Bus

Rail, Zinc-Plated

Steel (Documented in 2001)

The images below depict ZINC

whiskers found growing on a zinc electroplated steel bus

rail. This rail also has a yellow chromate finish which obviously

did not inhibit whisker formation. Whiskers up to several

millimeters long were observed. The user of this bus rail determined

the zinc whiskers were the root cause of catastrophic electrical shorting

failure during a thermal vacuum test.

ADDITIONAL

GALLERY of Zinc Whisker Photos on this Bus Rail

Source: Anonymous

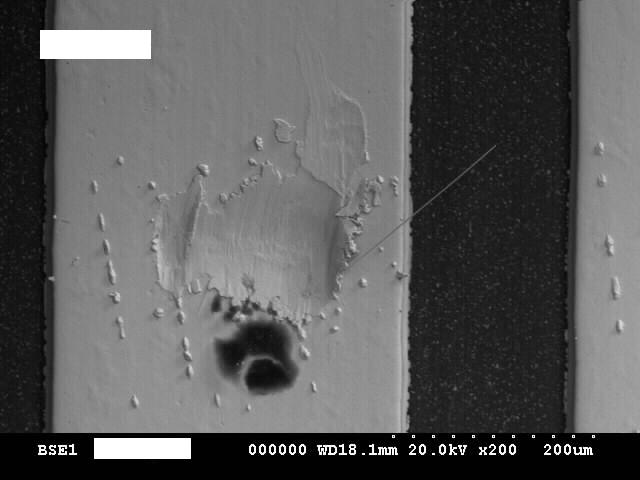

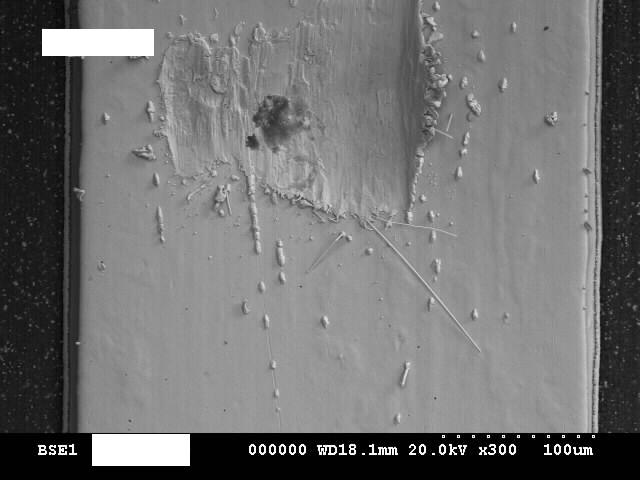

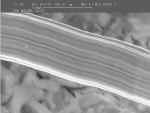

Bus Bar, Tin-Plated Copper

The following bus bar is made of copper that has been tin-coated.

It was installed in manufacturing equipment used by a large paper mill in

Sweden. It is suspected that tin whisker growth from bus bars like

this one may have initiated Metal Vapor Arcs on at least three separate

occasions resulting in significant damage and equipment down-time.

Read more about the tin whiskers on this bus bar

Sample provided by Anders Johansson

Optical Photos courtesy of NASA-GSFC

SEM photos courtesy of Lyudmyla Panashchenko

Cable

Trays

The following images document the growth of zinc

whiskers from zinc-coated steel wire cable trays made by

two different manufacturers. Each cable tray is reportedly made from

"pre-galvanized"

steel where pre-galvanizing indicates that the steel wire was hot

dip galvanized (i.e., zinc coated by immersion into molten

zinc) and then the cable trays were made by welding together the already

zinc-coated steel wire into the final cable tray structure.

A summary report documenting the zinc whisker growths on each cable

tray can be found here:

Zinc

Whiskers on "Cable Tray #1"

Zinc

Whiskers on "Cable Tray #2"

| Cable

Tray #1 |

|

|

|

|

|

|

| Cable

Tray #2 |

|

|

|

|

|

|

Samples provided by Greg Camburn

Analyses by NASA - GSFC

Card Guides

Card Guides, Tin-Plated Beryllium

Copper

|

|

In March 2006 the Space Shuttle Program discovered a

massive tin whisker infestation on the printed circuit board "card

guides" (aka card rails, card retainers) used to guide and hold the

printed circuit boards inside of numerous avionics boxes. The card

guides were made of beryllium-copper then plated with pure tin coating.

Tin whiskers up to 24-millimeters long were observed although most

whiskers were on the order of several millimeters in length.

It is strongly believed that the application of conformal

coating on the printed circuit boards helped to protect the circuitry from

extensive electrical short circuit problems during the >15 years of

field operations they endured. However, it is believed that one

failure during system level testing on the ground can be attributed to a

tin whisker that detached from a card guide and managed to bridge a pair

of conductors where the conformal coating was absent.

See

a Video Describing the Effort to Remove, Replace and Retest the Space

Shuttle hardware impacted by these whiskers.

See

a Shorter Video of Tin Whiskers on Card Guides in Space Shuttle hardware

Images Courtesy of the NASA Shuttle

Logistics Depot (NSLD)

Floor

Tiles (Raised) & Floor Support Structures

Floor Tiles and

Support Structures, Zinc-Coated Steel

The whiskers below are ZINC

WHISKERS. They were found growing on the zinc-coated

steel underside of raised floor tiles. In these examples the floor

tiles were part of a computer room in which zinc whisker debris was shed

from the floor tiles especially during maintenance activities within the

data center . The conductive whisker debris was distributed around

the room via the air cooling system. Ultimately, some whisker debris

was drawn inside of the electronic systems (e.g., servers, routers, disk

arrays) operating in the data center resulting in catastrophic and/or

intermittent short circuit failures.

See the presentation: "Zinc

Whisker Awareness: Could Zinc Whiskers Be Impacting Your

Electronics?" for More about Zinc Whiskers

ADDITIONAL

GALLERY of Zinc Whisker Photos on Raised Floor Structures

|

Optical Image of Zinc Whisker on Floor Tile

|

SEM Image of Zinc Whiskers on Floor Tile

|

SEM Close-Up of Zinc Whiskers on Floor Tile

|

|

SEM Image of

Zinc Whiskers on Floor Tile

|

SEM Image of Zinc Whisker on Floor Tile

|

|

Images

Courtesy of NASA-GSFC

Hardware

Lock Washer

The following lock washer is tin-plated.

Finding tin whiskers on this washer requires patience and familiarity with

proper techniques to illuminate and inspect for metal whiskers.

See

Video of this Lock Washer demonstrating how difficult it can be to inspect

for tin whiskers using optical methods

Images

Courtesy of NASA-GSFC

Pipe/Conduit

Steel Pipe, Zinc-Coated by

Process of Hot Dip Galvanized (HDG)

This steel pipe was zinc-coated using a "hot dip galvanization"

(HDG) process (i.e., immersed into molten zinc). Despite frequent claims

to the contrary, HDG coatings are NOT immune to the formation of zinc

whiskers as this specimen clearly shows. The pipe had been kept in a

warehouse storage for ~15 years prior to discovery of the whiskers.

Whiskers in excess of 10 millimeters have formed on this specimen.

Additional

Photos and Measurements of this Zinc Whisker Infested Pipe

(Courtesy of Lyudmyla Panashchenko)

Video

of This Pipe Demonstrating How Whiskers Flex in the Presence of Electric

Fields

Pipe sample donated to NASA Goddard by

Reima Lahtinen

Optical photos courtesy of NASA-GSFC

SEM photos courtesy of Lyudmyla Panashchenko

Terminal

Lugs

Terminal Lugs, Ring Type,

Tin-Plated

The terminal rings shown below are plated

with pure tin. These terminal rings are commonly used in

"crimp" type applications where a stranded wire is inserted into

the barrel and crimped in place. The ring terminal portion is most

often mounted using a nut and bolt to adhere the ring to a conductive

surface such as a chassis. Other terminal types shown include fast-on

(spade) terminals.

These photos are of "unused/loose

piece" terminal rings taken straight from the manufacturer's shipping

containers. In many cases the whiskers are found "inside" the crimp barrel of these

parts which is protected from abrasion that can dislodge whiskers from

the exposed surfaces.

See

a Video of Tin Whiskers found Inside the Crimp Barrel of One of the

Terminal Lugs shown below

Images

Courtesy of NASA-GSFC

Terminal Lugs, Spade Type,

Tin-Plated

Images

Courtesy of NASA-GSFC

Terminal Lugs, Tin-Plated,

Manufacturer "A"

Overall View of Tin-Plated Terminal Lug--Vendor A |

Tin

Whisker Inside Crimp Barrel--As-Received |

Close-up of Tip of Whisker |

Images

Courtesy of NASA-GSFC

Terminal Lug, Tin-Plated,

Manufacturer "B"

Images

Courtesy of NASA-GSFC

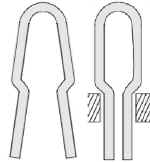

Test Points

Test Points, Tin-Plated

The test points shown here are "bright"

tin-plated phosphor bronze loops. They are commonly installed on PC

Boards as access points for attaching test leads/probes to monitor signals

and voltages during board level testing.

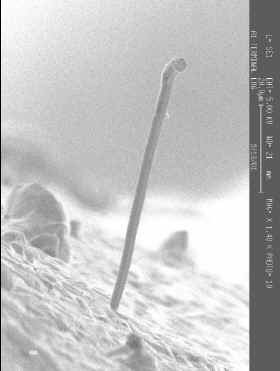

|

Overall Diagram of Test Point

|

Wide View of the Loop

|

Close-Up of Bend in Loop. Tin Whiskers are apparent

|

|

More Tin Whiskers on Test Loop

|

More Tin Whiskers on Test Loop

|

Detailed View of Tin Whiskers on Test Loop

|

|