|

About NPSL

Prohibited Materials

Parts Selection Table of Contents

Other Space Agency

EEE Parts Selection Listings

European Space Agency (ESA)

Japan Aerospace Exploration Agency

(JAXA)

|

Pure Tin Plating Prohibition

Policy:

Pure tin plating is prohibited as a final finish on EEE parts and associated

hardware

Reference:

Rationale:

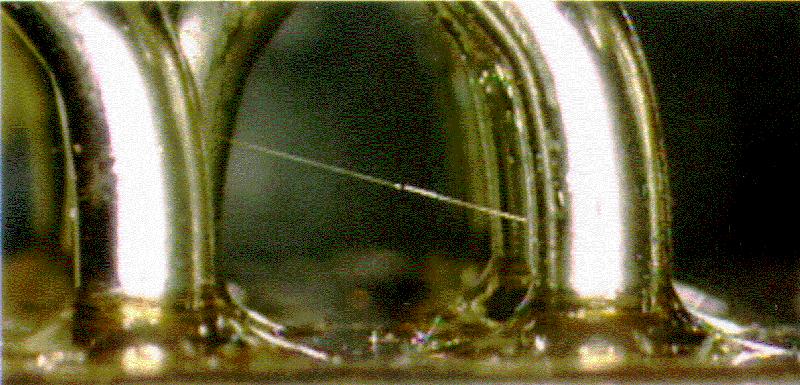

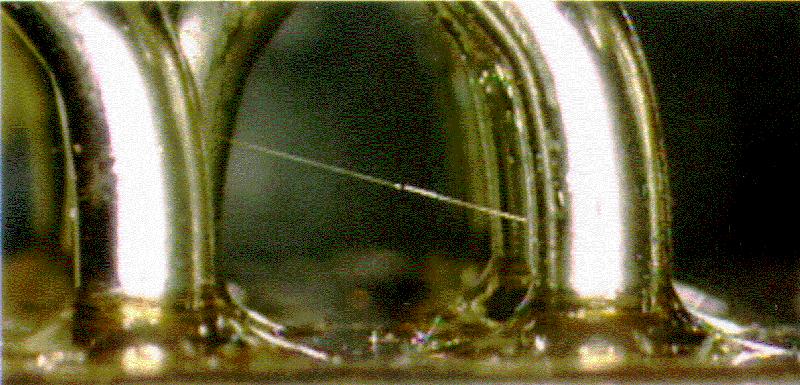

Pure tin finishes

are susceptible to the spontaneous growth of electrically conductive single

crystal structures known as tin whiskers. Over time these whiskers

may grow to be several millimeters (mm) long. Tin whiskers are capable

of causing electrical failures ranging from parametric deviations to sustained

plasma arcing that can result in catastrophic short circuits.

Several instances

have been reported where tin whiskers have caused system failures in both

earth and space-based applications including at least 3 separate events where

a tin whisker induced short circuit resulted in complete failure of a

commercial satellite.

The general risks

fall into four categories:

- Stable short

circuits in low voltage, high impedance circuits. In such circuits

there may be insufficient current available to fuse the whisker open

and a stable short circuit results. Depending on the diameter and length

of the whisker, it can take more than 50 milliamps (mA) to fuse one

open. More typical is ~10mA

- Transient short

circuits. At atmospheric pressure, if the available current exceeds

the fusing current of the whisker, the circuit may only experience a

transient glitch as the whisker fuses open.

- Metal Vapor

Arcing. If

a tin whisker initiates a short in an application environment

possessing high levels of current and voltage, then a VERY DESTRUCTIVE

phenomenon known as a Metal Vapor Arc can occur.

The ambient pressure, temperature and the presence of arc suppressing

materials also affect metal vapor arc formation. In a metal vapor arc,

the solid metal whisker is vaporized into a plasma of HIGHLY

CONDUCTIVE metal ions (more conductive than the solid whisker itself).

This plasma can form an ARC capable of carrying HUNDREDS OF

AMPERES. Such arcs can be sustained for long duration (several

seconds) until interrupted by circuit protection devices (e.g., fuses,

circuit breakers) or until other arc extinguishing processes occur.

This kind of arcing is happening in the metal vapor. When an arc

quenching agent (e.g., air) is present, more power must be installed

into the event to replace power lost to the non-interesting processes

happening in the quenching agent. Therefore, as air pressure is

reduced, less power is required to initiate and sustain a

whisker-induced metal vapor arc. For example, past experiments**

have demonstrated that at atmospheric pressures of about 150 torr, a

tin whisker could initiate a sustained metal vapor arc where the

supply voltage was approximately 13 Volts (or greater) and supply

current was 15 Amps (or greater). Tin (or other materials) from

the adjacent surfaces can help to sustain the arc until the available

material is consumed or the supply current is interrupted. Metal

vapor arcs in vacuum are reported to have occurred on at least three

commercial satellites resulting in blown fuses that rendered the

spacecraft non-operational.

** J.H. Richardson, and

B.R. Lasley, "Tin Whisker Initiated Vacuum Metal Arcing in

Spacecraft Electronics," 1992 Government Microcircuit

Applications Conference, Vol. XVIII, pp. 119 - 122, November 10 - 12,

1992.Basic Info on Tin Whiskers

- Debris/Contamination.Whiskers

or parts of whiskers may break loose and bridge isolated conductors

or interfere with optical surfaces

Recommendations:

At this time, the

only sure way of avoiding tin whiskers is not to use parts plated with

pure tin. Despite procurement specification requirements that prohibit

pure tin, errors sometimes occur resulting in pure tin plated components

being delivered. Therefore, users are advised to independently test and

analyze the plating composition of the products received as a verification

that pure tin plating is not in use. Simple visual inspection is generally

not sufficient because pure tin plating may appear similar to other plated

finishes such as tin/lead or nickel.

Utilization of procurement

specifications that have clear restrictions against the use of pure tin

plating is still recommended. Most, but not all, of the commonly used

military specifications currently have prohibitions against pure tin plating.

Studies have shown that alloying tin with a second metal can reduce the propensity

for whisker growth. Generally speaking, alloys of tin and lead (Pb) are acceptable where the alloy

contains a minimum of 3% Pb by weight. The effects on tin whisker

formation of alloying materials other than Pb are not well understood.

In the event pure

tin plated parts cannot be avoided, there are some additional processing

techniques that may be used to reduce but not eliminate the risks

associated with tin whiskers. The effectiveness of these approaches is

variable and most require further evaluation to determine their suitability

for long duration missions. Examples of these approaches include:

- Solder dipping

pure tin plated terminations and leads using a leaded solder. The effectiveness

of this approach at covering all pure tin plated surfaces can be variable.

- Application of

conformal coat material to pure tin plated surfaces. Conformal coat

appears to reduce the growth rate of tin whiskers, but whiskers are

still capable of growing through some conformal coat materials such

as polyurethanes.

- For some device

types manufacturers may be willing to replate surfaces using finishes

such as tin/lead or nickel which are substantially less prone to whisker

formation.

|